|

|

|

|

|

|

|

|

|

|

|

|

![]()

|

05-03-2010, 02:31 PM

05-03-2010, 02:31 PM

|

#31 |

|

Xanathar Thieves Guild

Join Date: January 8, 2001

Location: Charlotte,NC

Age: 60

Posts: 4,570

|

__________________

No |

|

|

05-03-2010, 02:36 PM

05-03-2010, 02:36 PM

|

#32 | |

|

Ninja Storm Shadow

Join Date: March 27, 2001

Location: Northport,Alabama, USA

Age: 62

Posts: 3,577

|

Quote:

__________________

Crustiest of the OLD COOTS "Donating mirrors for years to help the Liberal/Socialist find their collective rear-ends, because both hands doesn't seem to be working. Veitnam 61-65:KIA 1864 66:KIA 5008 67:KIA 9378 68:KIA 14594 69:KIA 9414 70:KIA 4221 71:KIA 1380 72:KIA 300 Afghanistan2001-2008 KIA 585 2009-2012 KIA 1465 and counting Davros 1 Much abliged Massachusetts |

|

|

|

05-03-2010, 03:42 PM

05-03-2010, 03:42 PM

|

#33 |

|

Jack Burton

Join Date: May 31, 2002

Location: Ireland

Posts: 5,854

|

John. Dude. Listen to me.

When did I say computer parts were not manufactured with oil? You are demanding evidence to an argument you just made up. I am open to the fact that you may have misinterpreted something. I however, do not see how this could be. I am going to give you an opportunity to walk me through how you got from what I said, to what you think I said.

__________________

Still I feel like a child when I look at the moon, maybe I grew up a little too soon... |

|

|

05-03-2010, 03:53 PM

05-03-2010, 03:53 PM

|

#34 | |

|

Ninja Storm Shadow

Join Date: March 27, 2001

Location: Northport,Alabama, USA

Age: 62

Posts: 3,577

|

Quote:

__________________

Crustiest of the OLD COOTS "Donating mirrors for years to help the Liberal/Socialist find their collective rear-ends, because both hands doesn't seem to be working. Veitnam 61-65:KIA 1864 66:KIA 5008 67:KIA 9378 68:KIA 14594 69:KIA 9414 70:KIA 4221 71:KIA 1380 72:KIA 300 Afghanistan2001-2008 KIA 585 2009-2012 KIA 1465 and counting Davros 1 Much abliged Massachusetts |

|

|

|

05-03-2010, 04:45 PM

05-03-2010, 04:45 PM

|

#35 | |

|

Ma'at - Goddess of Truth & Justice

Join Date: November 15, 2001

Location: Asheville, NC

Posts: 3,253

|

Quote:

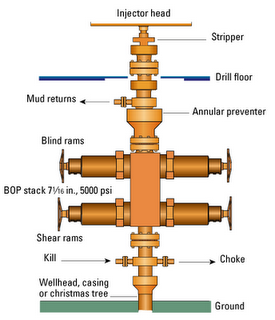

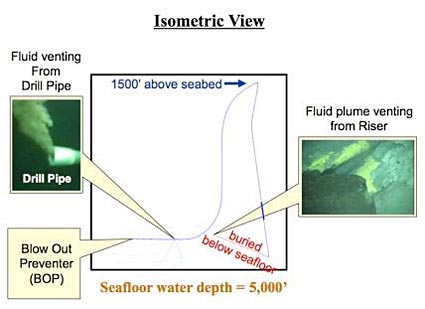

- We most certainly DO have the technology to drill in waters that deep and to solve problems like this one. In fact, we've gone DEEPER than the 5000 foot wd that this well was being drilled in. I might be off a bit, but I believe that the current water depth record is over 10000 feet in the western GOM. - Here's what is supposed to happen: At the sea floor is a massive piece of equipment known as a blow-out preventer. It's SOLE function is to prevent the massive pressure surges that occured here. A part of the BOP is a device called the shear ram. The hydraulically powered shear ram is supposed to sever the pipe and close it off to protect the rig and work crews from the flow of explosive oil and gas. Obviously that didn't happen. In addition to the shear ram the BOP has a series of cut-off valves. (Just like the main water cut off valve for your house but a LOT bigger.) If the Shear rams fail, the pressure valves can also be turned to cut off the flow. In some cases these valves can be controlled remotely and in others, they must be closed manually. IEven at these depths manual cut-off can be performed by remote submersible robots which have been designed expressly for this and utilized successly in hundreds of deep water operations. - What happened here is a case of catastrophic failure, NOT stupidity, NOT going beyond our technology. The pressure surge, left unchecked, caused the explosion that ended up sinking the drillship but likely also damaged the ram valves. The damaged shear rams failed - either to activate at all or in failing to completely close off the pipe. In addition the BOP stack probably sustained additional damage when the 5,000 foot pipe connecting the well to the rig was severed from the vessel as it sank. As a result, the shear rams and the additional valves could not be fully closed. Video shot by the robotic submarines (a.k.a. remote operated vehicles or ROVs) seems to indicate that oil is leaking from three spots in a pipe that is laying on the seafloor. The pipe would have to be a portion of the riser, which would have to still be attached to the BOP, but crimped and bent over. An uncuttable piece of joint lodged in the shear ram would perhaps explain why the ROVs haven't been able to subsequently engage the ram. An uncuttable piece of joint lodged in the shear ram would perhaps explain why the ROVs haven't been able to subsequently engage the ram. That leaves the ONLY option as drilling a relief well to pump cement or a synthetic fluid heavier than crude into the well to suppress the flow. Unfortunately that's a three month project. So it's NOT accurate to say that we don't have the technology and that we're going BEYOND the limits of what we can do safely, TL. Questions about WHY the rams failed are legitimate though. Especially considering that this well had not one, not two, but FIVE hydraulic shear rams - two Cameron TL double shears and a Cameron TL single shear. And no, I don't think this is a just one big "OOPSIE" either. By the way, here's an EXCELLENT link to some pics. Scroll down to pic 10 to see the robot in action. http://www.boston.com/bigpicture/201...louisiana.html

__________________

“Every tavern’s an opportunity, I say.”

Last edited by Micah Foehammer; 05-03-2010 at 04:51 PM. |

|

|

|

05-03-2010, 05:12 PM

05-03-2010, 05:12 PM

|

#36 |

|

Ninja Storm Shadow

Join Date: March 27, 2001

Location: Northport,Alabama, USA

Age: 62

Posts: 3,577

|

interesting stuff there Micah, yeah I remember while I lived in panhandle of Florida voting several times to alow drilling off the panhandle in shallower water, but we lost... oh well such is life.

__________________

Crustiest of the OLD COOTS "Donating mirrors for years to help the Liberal/Socialist find their collective rear-ends, because both hands doesn't seem to be working. Veitnam 61-65:KIA 1864 66:KIA 5008 67:KIA 9378 68:KIA 14594 69:KIA 9414 70:KIA 4221 71:KIA 1380 72:KIA 300 Afghanistan2001-2008 KIA 585 2009-2012 KIA 1465 and counting Davros 1 Much abliged Massachusetts |

|

|

05-03-2010, 06:25 PM

05-03-2010, 06:25 PM

|

#37 | |

|

Apophis

Join Date: October 19, 2001

Location: New York

Age: 37

Posts: 4,666

|

Quote:

|

|

|

|

05-03-2010, 07:26 PM

05-03-2010, 07:26 PM

|

#38 |

|

Jack Burton

Join Date: May 31, 2002

Location: Ireland

Posts: 5,854

|

Well, you can't say I didn't offer you the opportunity to explain yourself here *Shrug*.

__________________

Still I feel like a child when I look at the moon, maybe I grew up a little too soon... |

|

|

05-03-2010, 07:53 PM

05-03-2010, 07:53 PM

|

#39 | |

|

Ma'at - Goddess of Truth & Justice

Join Date: November 15, 2001

Location: Asheville, NC

Posts: 3,253

|

Quote:

http://cfr.vlex.com/vid/250-516-blow...tions-19694952 And just so everyone knows what a BOP looks like:  Note that this is NOT the actual BOP stack used. The one actually used would have been much bigger. In fact, it's possible that attempts to close the rams HAVE been successful, if not completely then partially. Read on: "Mr. Hayward (BP) said the blowout preventer was tested 10 days ago and worked. He said a valve must be partly closed, otherwise the spillage would be worse. There are a number of things that can go wrong with a blowout preventer, said Greg McCormack, director of the Petroleum Extension Service at the University of Texas, which provides training for the industry. The pressure of the oil coming from below might be so great that the valves cannot make an adequate seal. Or in the case of a shear ram, which is designed to cut through the drill pipe itself and seal it off, it might have encountered a tool joint, the thicker, threaded area where two lengths of drilling pipe are joined. Still, Mr. McCormack said, “something is working there because you wouldn’t have such a relatively small flow of oil.” If the blowout preventer were completely inoperable, he said, the flow would be “orders of magnitude” greater." However oil is now flowing through the BOP and out into the water immediately above the well site on the sea bed. When the site was visited by a small remotely operated vehicle with cameras they showed that the riser, the pipe that normally carries the oil from the sea bed to the surface, had kinked over when the rig sank, and oil was coming from three places: The Coast Guard said it had not detected oil coming from the well Friday and assumed post-accident efforts to activate the blowout preventer “a huge stack of valves sitting atop the wellhead on the sea floor” had been successful. But later trips by the remotely operated vehicles (ROV’s), discovered oil shooting from the end of the pipe-like riser that had connected the rig to the blowout preventer. A second, smaller leak was found in a section of drill pipe near the wellhead. That 21-inch-diameter riser had become detached from the rig when it sank. In the process, it was folded over at a 90-degree angle just above the wellhead, which had the effect of kinking it like a garden hose and constraining the flow of oil from the well. It now sits in a long, meandering mess on the ocean bottom. This helps explains why oil was not initially thought to be seeping.  The preferred option, he said, is still to find a way to engage the blowout preventer. That fix, if it works, could be handled in a matter of days, he said. But if that doesn't work, the other option is to drill a deep “relief” well into the damaged well and stem the flow of oil, though that option could take several months, Suttles acknowledged. He said his team would spend the next several days trying to determine the best method. There is a report from a survivor that says that the well was shut in and they were going through the process of separating the rig from the well, and moving it off. They began by cleaning out the drilling mud from the riser, replacing it with sea water. However, when they re-opened the valves at the top of the well, the pipe in the well had become filled with gas from the well, under considerable pressure, and this “Kicked” the well as the valve opened. Gas, as the pressure gets less as it moves up the pipe, expands much more than oil. And unfortunately in the process of disconnection, the pressure to hold the gas, which comes from the density of the drilling mud in the riser initially, had been removed as part of the disconnection process. So the high pressure gas was able to blow all the sea water in the riser out onto the deck of the rig. (This happens extremely quickly, well below a minute) The gas then followed, and as it flowed out of the pipe at the top of the well there was some hot source that caused it to ignite. (This could even be from a static electricity spark). Because of the depth of the well, the pressure in the bottom of the well was in the 30-40,000 psi range. (Note: The 30-40 kpsi estimate might be overstated slightly. You convert the drilling mud weight in lbs/gal to psi/ft and then multiply by the subsea drilling depth - 18,000 feet in this case. I don't know the actual mudweight used but from past experience, it likely would have been somewhere between 17 and 18 lbs/gal. 1 US gallon = 0.133680556 cubic feet 18 lbs/ gal = 134.649 lbs / cubic foot = 134.649 lbs per sq ft / ft 134.649 lbs pounds per square foot = 0.935 psi 18 pounds per gal = 0.935 psi/ft Bottom hole pressure = 18,000 ft x 0.935 psi/ft = 16,800 psi I think I did that right. That's high but not the 40 kpsi quoted.) Part of the problem that arises with flows at that pressure (It still applies at the 16,800 psi but to a slightly lesser degree) is that any abrasive particles (such as small pieces of rock) will cut through metal at the speeds at which it is carried. (Such jets were used to remove the damaged tops of the wells in Kuwait after the Gulf War, for example. At driving pressures above 3,500 psi a liquid flow containing abrasives such as the sand for the drilled rock, can erode metal of more than an inch thick at significant parts of an inch a minute traverse speed.) So that it is possible that as the BOP started to function the high-velocity flow may have eroded part of the system to allow some fluid to bypass the plug that the BOP inserted. If that happened then the continued flow would just enlarge the passage again fairly quickly, so that the BOP will become ineffective. At this stage there does not appear to be that great a driving pressure for the oil coming out of the well. (If there were, the flow would be more directed horizontally) This suggests that the BOP did at least partially function, and that the passage may have been eroded by the particles in the gas and oil now escaping." All of this comes from a site called "The Oil Drum". Now it's possible that your "grapevine source" MIGHT be right - heaven knows it's NOT out of the realm of possibility. It might be nice if you had a linkable source to put that information into context. Oh well, no matter. I do know from first hand experience that these drilling crews take safety procedures seriously - they actually get bonuses (or at least they used to) for having no lost time accidents, passing safety inspections, etc. They work HARD at keeping things safe on those rigs and do not look kindly on people who don't. FYI, the Deep Horizon was not some cheap drilling rig either. It was a 5th generation deep ocean drilling rig custom designed and built especially for drilling in deep water.

__________________

“Every tavern’s an opportunity, I say.”

Last edited by Micah Foehammer; 05-03-2010 at 08:07 PM. |

|

|

|

05-03-2010, 08:06 PM

05-03-2010, 08:06 PM

|

#40 | |

|

Apophis

Join Date: October 19, 2001

Location: New York

Age: 37

Posts: 4,666

|

Quote:

Another supplementary reading to add on to what Micah posted can be found here. I think it has some relevance. http://www.theoildrum.com/node/6427 Edit* Micah, I didn't even realize you linked to TheOilDrum. It is nice to meet another Oil Drum reader! Last edited by SecretMaster; 05-03-2010 at 08:09 PM. |

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Baby needs a name... | Madman-Rogovich | General Discussion | 13 | 03-27-2006 09:47 AM |

| My baby boy | pritchke | General Discussion | 28 | 08-07-2005 06:42 AM |

| XXXXXXXXXXX in order to Drill in Alaska | Timber Loftis | General Conversation Archives (11/2000 - 01/2005) | 20 | 03-14-2003 01:51 PM |

| My baby boy. | TheDutkanator | General Conversation Archives (11/2000 - 01/2005) | 7 | 10-29-2001 01:08 PM |

| POLL : Anomen (you know the drill) | Mirac Honorguard | Baldurs Gate II Archives | 31 | 09-26-2001 04:55 PM |